Because of AED’s life saving capabilities, maintaining them through inspections is a high priority. Here are 5 benefits to using AED inspection software during inspections.

Automated External Defibrillators (AEDs) are life-saving devices designed to provide immediate medical assistance during cardiac emergencies. Use of an AED within the first few minutes of a cardiac arrest event can bring the survival rate to as high as 74%. The effectiveness of AEDs make them invaluable tools for protecting employee and public safety. Regular maintenance and inspections ensure that AEDs are functional, reliable, and ready to work in the moment they are needed.

Figuring out the best way to manage AED inspection and maintenance is no easy task. Luckily, advancements in technology have led to the development of AED inspection software, which streamlines and enhances the inspection process. AED inspection software can manage AED inspections on their own, or combine AED inspections into a route with other fire and/or life safety equipment inspections. In this article, we will explore five key benefits of using AED inspection software.

1. Improved Efficiency and Accuracy

One of the primary advantages of AED inspection software is its ability to streamline the inspection process, resulting in improved efficiency and accuracy. Traditional paper-based methods often involve manual data entry and physical record keeping, which can be time-consuming and prone to human error. Manual reporting is tedious, and it can complicate the process of ensuring that AEDs are inspected properly and on time.

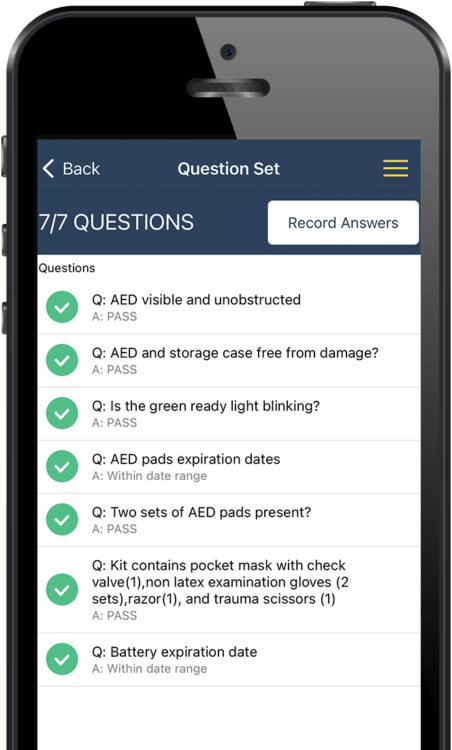

With AED inspection software, field technicians can easily record inspection data using mobile devices, such as smartphones or tablets. The AED inspection software shows the field technician where each AED is located, the last time it was inspected, and when the next inspection is due. Performing an inspection is as simple as scanning a barcode or QR code and answering the questions on the screen.

AED inspection software automates data collection and eliminates the need for manual data entry, reducing the chances of errors. This streamlined process saves time for both the field technicians and AED or life safety program administrators, allowing them to focus on other critical tasks.

Inspection App Solutions

2. Centralized Data Management

AED inspection software offers a centralized platform for managing inspection data. All inspection records, including device information, maintenance history, and inspection results, can be stored securely in a digital database. This centralized approach enables easy access to historical data and facilitates comprehensive on-demand reporting and analysis.

Administrators can generate reports on inspection trends, identify recurring issues, and track the overall performance of their AED program. Moreover, this digital record-keeping ensures that critical information is readily available during audits or in the event of a legal inquiry.

3. Inspection and Maintenance Task Automated Scheduling

One of the challenging aspects of an AED inspection program can be managing inspection and maintenance due dates. Generally, inspections need to be performed once per month. Additionally, AED pads and batteries have expiration dates that must be carefully managed. AED inspection software takes all the stress out of the process by tracking when the last inspection was performed and automatically scheduling the next one at the appropriate time. Accessing a scheduled inspection is as simple as logging into the mobile app to find it added to the digital to-do list.

When it comes to AED pad and battery replacements, AED inspection software offers two different workflows to meet customer needs. The first option is to include questions on the monthly inspection form which require the field technician to check expiration dates on the pads and batteries. The second workflow is to setup automated pad and battery replacement tasks within the software. For each AED’s pad set and battery, the installation date is input into the equipment record. The AED inspection software will trigger a replacement task every 5 years, or according to the timing required by the customer or manufacturer. This makes the monthly inspection quicker and easier by removing the requirement to repetitively check expiration dates each month.

4. Compliance and Regulatory Adherence

Maintaining compliance with regulations and industry standards is crucial for AED program administrators. AED inspection software helps organizations adhere to compliance requirements by incorporating relevant regulations and guidelines into the inspection process.

The software can be customized to include specific inspection checklists, protocols, and regulatory requirements as required by the local authority having jurisdiction. Field Technicians are guided through each step of the inspection process, ensuring that all necessary elements are addressed. By maintaining compliance, organizations mitigate risks, improve the safety of their AED program, and demonstrate their commitment to public safety.

5. Enhanced Documentation and Audit Trail

Documentation plays a vital role in ensuring accountability and traceability within an AED inspection program. AED inspection software enhances documentation practices by automatically generating comprehensive inspection reports and maintaining a detailed audit trail.

Each inspection is time-stamped with record of the inspector’s identity. This automatic record keeping makes it easier to track responsible parties and maintain a history of the inspections/maintenance work that has been completed.

In case of an incident or investigation, this audit trail becomes invaluable for reconstructing events and identifying potential areas of improvement. Moreover, digital documentation reduces the reliance on physical storage space and minimizes the risk of document loss or damage.

Managing and keeping track of Automated External Defibrillators (AEDs) in your workplace, as well as meeting inspection and maintenance requirements, can pose challenges. It can be difficult to remember the location of each device and the date of its last inspection. Additionally, documenting and reporting inspection dates and results can be a tedious task. To effectively execute an AED inspection program, the recommended approach is to utilize specialized life safety equipment inspection software like InspectNTrack.

With InspectNTrack, each AED is assigned a unique identifier through the use of barcodes or QR codes. The software maintains an inventory of all AEDs, including essential details such as their location, manufacturer, model number, and manufacturing date. It also collects expiration dates for pads and batteries. The software facilitates the setup and management of a monthly inspection program and pad and battery replacement tasks.

InspectNTrack automatically schedules tasks when AED inspections or parts replacements are due. Users are prompted to scan the barcode or QR code on each AED and subsequently answer inspection questions, similar to the ones mentioned earlier. Inspection results are stored within the software, and inspection reports can be generated whenever needed. Ensuring compliance is as simple as a click of a button.

In cases where an AED fails an inspection, InspectNTrack is configured with a customized workflow to ensure the failure is adequately documented and responsible parties are notified. Workflows may involve sending email notifications, creating work orders in your work order management system, logging the problem in InspectNTrack’s discrepancy module, or generating consolidated failure reports. These workflows are designed with the primary objective of promptly identifying AED issues and tracking them through to corrective actions.

By utilizing the barcode-based AED inspection software provided by InspectNTrack, your team can efficiently and affordably inspect AEDs within seconds. This system enables you to effortlessly monitor and oversee all your AEDs through a centralized dashboard.

InspectNTrack AED Inspection Software Makes AED Inspections Easier

AED inspection software offers numerous benefits that enhance the efficiency, accuracy, and compliance of AED programs. By digitizing the inspection process, organizations can streamline data management, improve accountability, and ensure the timely maintenance of their AED devices. With AED inspection software, maintaining AED devices is easier than ever.

Taking steps to maintain AEDs according to manufacturer specifications reduces the risk of device failures during emergencies. Furthermore, the comprehensive documentation and audit trail provided by AED inspection software facilitates regulatory compliance and enhances the overall safety of AED programs.

As technology continues to advance, leveraging AED inspection software becomes an essential component in maintaining reliable and effective AEDs that are ready to save a life at any moment.

Conclusion

AED devices are powerful tools for saving lives, so long as they function properly. In order to certify that they are operating correctly, regular inspections should be completed on AED devices. Because these medical tools require frequent checks, manually maintaining records for inspections and testing can be difficult.

Instead of manual inspections, AED inspection software can be used to:

- Increase efficiency and accuracy

- Provide a centralized location for data management

- Generate automated scheduling for inspections and maintenance tasks

- Simplify compliance and regulatory adherence

- and create an enhanced documentation and audit trail

AED inspection software provides users with many benefits that contribute to an overall safer workplace environment. For more information on InspectNTrack’s AED inspection software offerings, request a demo at the bottom of the page or talk with one of our specialists.