How Can Inspection Software Keep My Business Safe?

The safety of your employees, your customers, and your business is no small task. Keeping everyone and everything safe requires time and work, and you don’t want safety concerns to interrupt your daily tasks.

Completing the required safety inspections for your business can take time and cost your business when done incorrectly. But we know they have to get done. That’s why we’ve created this list of 3 ways to improve your safety inspection process by using inspection software.

Inspection App Solutions

1. Automate, Automate, Automate

The first way to improve your inspection process is through automation. The definition of automate is to run something swifty using machines or software, instead of manual human labor. This is precisely what safety inspection software does.

Instead of having a person manually create reports after each safety inspection, have your inspection software pull the reports automatically. Instead of manually tracking the status of each asset, have your inspection software automatically track the status. Instead of spending time trying to remember when the next safety inspection is due — and risking a fine if you miss a deadline — have your inspection software automatically notify when it’s time for the next inspection.

Automation is the key to efficiency. By setting up the right automated processes within the right safety inspection software, you ensure that time isn’t wasted.

2. Standardize Your Process

The second way that inspection software will help you improve your safety inspection process is through standardization. The best process is worth nothing if not consistently implemented — and the best way to consistently implement a safety process is through safety inspection software. Not only do you keep the workplace safe, but you also follow safety guidelines.

It is almost impossible to guarantee that the same person will perform the safety inspection every single time, over the lifetime of a business. Each time a new person performs the inspection, if there is no clear process, then the integrity of the inspection is compromised. By leveraging a safety inspection software, you establish a standard for how the inspection is to be performed, regardless of who is doing it.

Let’s explore how.

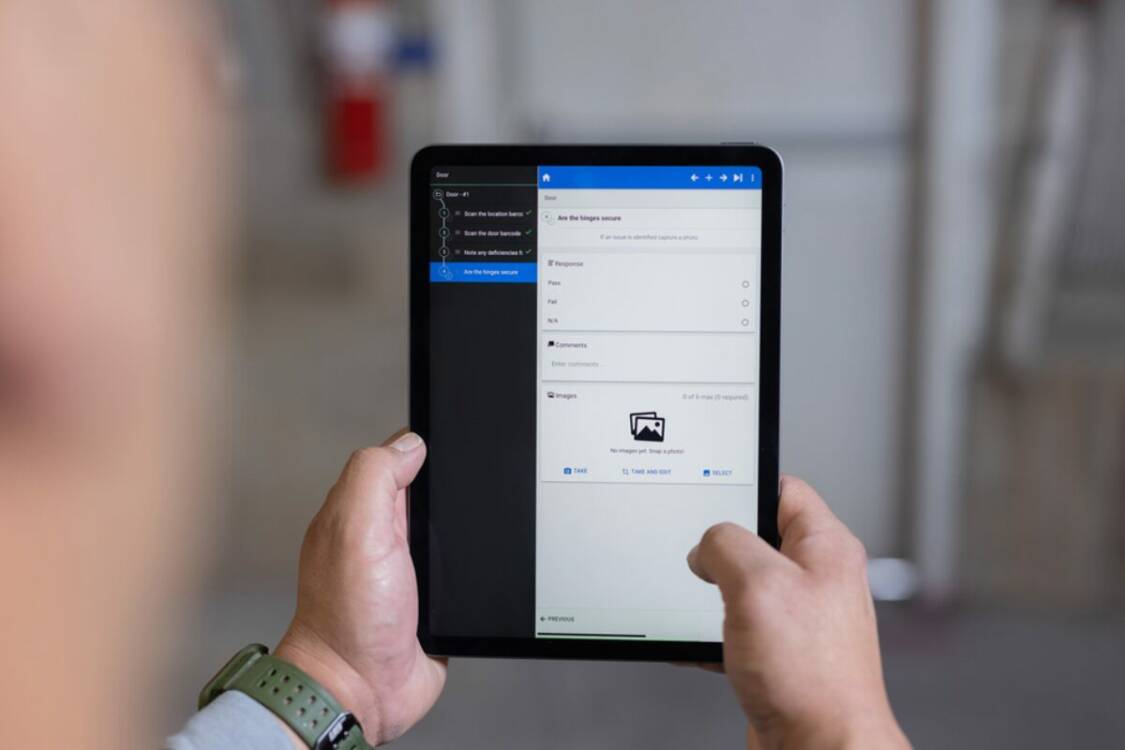

Imagine it’s time for the next safety inspection, and the person who normally does your inspections is out sick. Now, the only person available to perform the inspection is Joe — your newest hire. Joe has only been working for you for two weeks, and has never performed a safety inspection in his life. Without a standardized process and the right tools, this could be a real issue. Thankfully, you’re using inspection software to help perform all your safety inspections (in fact, that’s even how you knew another inspection was due!).

Now, Joe simply has to understand how to scan each asset, and the inspection software will ensure he doesn’t miss anything. Because if he does miss an asset, the software will flag that asset as unchecked. Thanks to your inspection software, you can rest easy knowing that Joe can perform a safety inspection to the same standard of excellence as the most seasoned safety inspector.

3. Keep Your Reports Close

The final way that inspection software will help your inspection process is via it’s reporting capabilities.

If you don’t know the status of each of your safety assets, then you really don’t know how safe you are. The reporting function within inspection software allows you to view the status of each of your assets. You can quickly see which assets are in need of maintenance, or when the next inspection needs to be performed. Simply put, without reporting, it wouldn’t matter how efficient or how often you performed a safety inspection – you would never know what actions need to be taken to ensure the security of your employees, customers, and business.

Save Money With Our Inspection Software

So, if you’re looking for ways to improve your safety inspection process, remember these 3 points: Automate, standardize, and report by using inspection software. To learn more, contact InspectNTrack today.

Other Helpful Articles