Eyewash Station Inspection Software — Simplify Inspections and Testing

Eyewash Station Inspection Software from InspectNTrack is a powerful, barcode-enabled solution designed to streamline eyewash station inspections, improve regulatory compliance, and eliminate manual paperwork. Built for life safety and EHS professionals, our mobile inspection app helps you stay on schedule, stay compliant, and stay in control of safety programs.

Routine eyewash station inspections are essential for workplace safety and compliance with OSHA 29 CFR 1910.151 and ANSI Z358.1 standards. InspectNTrack’s eyewash station inspection software automates inspection workflows so you never miss a required check again. Whether you’re inspecting a single unit or managing dozens across multiple locations, our inspection platform ensures accuracy, documentation, and peace of mind.

Solutions

Key Features & Benefits

InspectNTrack includes features that enable efficient, compliant, and easy inspections:

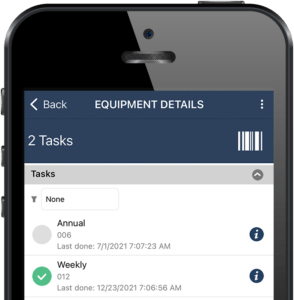

Automated Scheduling: Set recurring inspection frequencies and never miss a weekly or monthly check.

Barcode Scanning: Scan 1D, 2D, QR, or existing manufacturer barcodes to instantly access inspection history and equipment details.

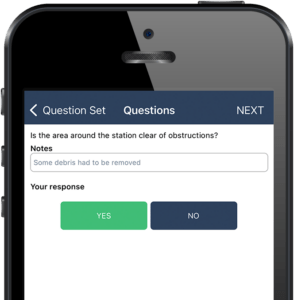

Custom Inspection Forms: Tailor inspection questions and answer fields to your standards or regulatory checklist.

Inspection Routing: Route planning keeps technicians organized and efficient, minimizing missed stations.

Mobile App Access: Technicians can perform inspections directly in the field using Android, iOS, or Windows devices.

Discrepancy & Corrective Actions: Automatically log issues, assign corrective tasks, and notify the right personnel.

Compliance Documentation: Generate reports to support audits and demonstrate adherence to OSHA, NFPA, and ANSI standards.

Why Choose InspectNTrack Eyewash Station Inspection Software

InspectNTrack’s eyewash station inspection software is powerful enough for complex safety programs yet intuitive for everyday use. It centralizes all inspection data, eliminates paperwork, and ensures your team always has up-to-date information on station performance across your facilities.

With automated alerts, detailed history tracking, and corrective action workflows, you’ll maintain compliance and protect employees more effectively than with traditional inspection methods.

Corrective Action & Issue Management

When an eyewash station fails inspection, our software doesn’t just notify you—it triggers workflow actions such as:

Logging discrepancies with categories, photos, and notes

Creating incident records

Sending automated notifications to responsible personnel

This makes it easy to track root causes, resolve issues quickly, and prevent recurring problems.

Easy Mobile Inspection and Reporting

Using the mobile app, technicians can complete eyewash station inspections on-site and instantly sync results to a central dashboard. Accessible inspection history and audit-ready reports help safety teams:

Validate compliance

Track performance trends

Document corrective maintenance

Improve workplace safety outcomes

Best of all, your inspection records are organized in one searchable platform—no more binders, tags, spreadsheets, or lost paperwork.

Get Started With Inspection Software

Take control of your safety program with InspectNTrack eyewash station inspection software. From barcode scanning to automated scheduling and mobile reporting, it’s everything you need to make inspections faster, more reliable, and compliant with industry standards.