Warehouse Inspections | Digital, OSHA-Compliant Solutions

Warehouses are high-traffic, high-risk environments, making a regular warehouse inspection program vital for safety and compliance. This makes routine safety inspections essential—not only for compliance, but for protecting personnel, assets, and operational uptime. InspectNTrack helps warehouses efficiently manage required safety inspections, automating the warehouse inspection program with scheduling, tracking, and reporting in accordance with OSHA and NFPA standards.

InspectNTrack’s customizable equipment categories and inspection questions make it possible to manage all facets of a warehouse inspection program within a single system.

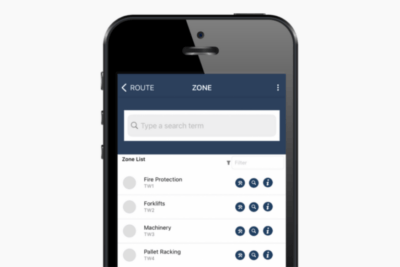

InspectNTrack organizes equipment into routes and zones to simplify the scheduling of different equipment and inspection types throughout each building and across your entire footprint. Multi-site setups are offered for companies with multiple locations. InspectNTrack offers user initiated or automated inspection scheduling, guided field inspections, and robust reporting.

Industries

Common Warehouse Inspection Areas

Fire Extinguisher Inspections in Warehouses

Fire extinguishers are a critical part of warehouse safety and are regulated under OSHA 29 CFR 1910.157 and NFPA 10. These standards require:

- Monthly visual inspections

- Annual maintenance by a qualified professional

- Hydrostatic testing every 5–12 years, depending on type

Most warehouses hire fire extinguisher service companies to handle inspections, often paying $40–$100 per extinguisher annually. If monthly visual checks are outsourced, costs can increase to $9–$15 per extinguisher, per month, totaling hundreds or thousands annually for mid-size facilities.

But here’s the truth: monthly visual inspections don’t require certification or outside help. They can legally and effectively be performed by your warehouse employees—as long as they follow OSHA’s required checklist items. Most InspectNTrack customers who bring monthly fire extinguisher inspections in-house not only cover the cost of the software but actually start saving money!

Save Costs with InspectNTrack

InspectNTrack guides your in-house team through compliant monthly fire extinguisher inspections using a mobile app with step-by-step NFPA 10 compliant prompts. Users check and confirm:

- Proper placement and mounting

- Unobstructed access

- Pressure gauge in operable range

- Pin and tamper seal intact

- No visible damage or corrosion

- Updated inspection tag

Each warehouse inspection is automatically logged and time-stamped, with data stored securely for audit-readiness. InspectNTrack empowers warehouses to reduce dependency on external vendors, ensure compliance, and eliminate recurring service fees—without sacrificing inspection quality or documentation.

Forklift & Powered Truck Inspections

Warehouses using forklifts, pallet jacks, and powered industrial trucks are required to conduct pre-shift inspections under OSHA 29 CFR 1910.178(q)(7). These checks must occur at the beginning of each shift, and employers are responsible for documenting each inspection and ensuring unsafe equipment is removed from service.

Traditionally, this has resulted in warehouses filling file cabinets with paper inspection logs—creating a burden for both compliance tracking and historical documentation.

Go Paperless with InspectNTrack

InspectNTrack replaces paper forms with a fast, simple mobile app. Operators scan a barcode affixed to the forklift or truck and are immediately prompted with a custom checklist tailored to OSHA’s requirements. This includes checks for:

- Brakes, horn, lights, and backup alarms

- Tires and forks for visible wear or damage

- Battery or fuel levels

- Leaks, cleanliness, and seatbelt condition

- Load-handling controls and steering response

Once submitted, the inspection is:

- Time- and user-stamped

- Automatically stored in the cloud

- Available for review, reporting, and audits anytime

No more chasing paper logs. No more forgotten checks. No more rooms full of file cabinets.

Warehouse Racking Inspections

Warehouse racking systems are commonly used for storage and inventory organization—but they also present serious safety risks if damaged or overloaded. Regular warehouse racking inspections are critical for identifying structural concerns such as bent uprights, dislodged beams, or improper loading.

InspectNTrack streamlines racking inspections by enabling warehouse employees to scan a barcode at the beginning of each aisle to launch a digital checklist. When damage is found, the inspector can scan the specific location ID to document the issue, add comments, and upload photos in real time.

Seamless Integration with Existing Barcodes

InspectNTrack is fully compatible with WMS bin location or position barcodes already applied to your racking. This eliminates the need for duplicate labeling and enables:

- Fast, targeted damage reporting

- Photo documentation and location-based records

- Searchable inspection history tied to exact rack sections

The result? Safer racks, faster inspections, and fully digital records ready for audits or repairs.

Ladder Inspections

Ladders are among the most commonly used—and most overlooked—pieces of equipment in a warehouse environment. According to OSHA 29 CFR 1910.23, employers must ensure that ladders are inspected regularly and maintained in safe condition. While frequent visual checks are recommended, a formal annual inspection is a key requirement for compliance and injury prevention.

InspectNTrack simplifies this process by allowing warehouse inspection managers or designated staff to conduct annual ladder inspections digitally. Using a barcode placed on each ladder, inspectors can:

- Launch a preconfigured checklist covering rails, steps, hardware, labels, and stability

- Document any damage or wear with photos and notes

- Mark ladders as removed from service if unsafe

- Maintain digital records tied to each ladder for future reference

These records are securely stored and easily retrievable for audits or maintenance planning, eliminating the need for paper logs or manual spreadsheets.

Safety & First Aid Inspections

Safety and first aid equipment play a critical role in emergency preparedness and response within warehouses. OSHA requires that items such as first aid kits, AEDs (Automated External Defibrillators), and spill kits be inspected and maintained in a ready-to-use condition in accordance with OSHA 29 CFR 1910.151, 1910.266 App A, and ANSI/ISEA Z308.1 standards for first aid kit minimum requirements. However, these checks are often missed or inconsistently documented, leading to non-compliance and safety risks.

InspectNTrack makes it easy to stay compliant by providing digital inspection workflows for all safety and first aid equipment. Using barcodes affixed to each item, staff can quickly:

- Launch a checklist to verify contents, expiration dates, and operability

- Log missing or expired items with comments and photos

- Schedule replenishment actions or mark equipment out of service

Each warehouse inspection is digitally logged with a timestamp and inspector ID, creating a secure, audit-ready trail. This eliminates the need for paper forms and ensures that all emergency resources are fully stocked and functional when needed most.

Ensure Compliance. Increase Accountability.

From daily forklift inspections to annual ladder and first aid kit checks, InspectNTrack digitizes every aspect of warehouse inspections. With mobile-friendly checklists and audit-ready records, it’s the trusted solution for safety managers across the warehousing industry.